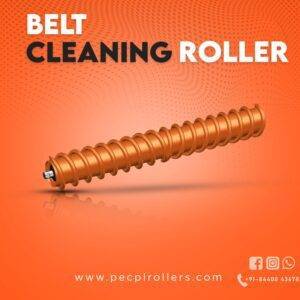

Self Cleaning Finned Tail Pulley

PECPL Conveyors & RollersConveyor Pulley| Material: | The Self Cleaning Finned Tail Pulley is made from high-quality materials such as mild steel, stainless steel, or aluminium |

|---|---|

| Application: | The Self Cleaning Finned Tail Pulley is designed for use in conveyor systems to remove material build-up from the tail pulley. It is commonly used in industries such as mining, quarrying, and construction |

| Structure: | The Self Cleaning Finned Tail Pulley is designed with fins or blades that are attached to the pulley surface. These fins or blades rotate along with the pulley, scraping any material buildup from the surface |

| Bearing Type: | The Self Cleaning Finned Tail Pulley typically uses sealed ball bearings or roller bearings to support the pulley and allow it to rotate smoothly |

| Type: | The Self Cleaning Finned Tail Pulley is available in various types, such as crowned or flat, depending on the specific application requirements |

| Transport Package: | The Self Cleaning Finned Tail Pulley is typically shipped in a protective wooden crate to ensure safe transportation |

| Samples: |

Samples of the Self Cleaning Finned Tail Pulley can be provided upon request

|

|---|

| Customization: |

The Self Cleaning Finned Tail Pulley can be customized to suit specific requirements, such as different sizes, materials, and bearing types

|

|---|

Description

Basic Info.

The Self Cleaning Finned Tail Pulley is a type of conveyor pulley that is designed to remove material buildup from the tail pulley to ensure smooth and efficient operation of the conveyor system.

Product Description

Product Description

The Self Cleaning Finned Tail Pulley is a high-quality and reliable solution for conveyor systems that require effective material buildup removal from the tail pulley. Its durable construction and effective design make it ideal for use in heavy-duty industries such as mining and quarrying.

|

Roller Properties

The Self Cleaning Finned Tail Pulley does not have roll picking properties as it is not a type of conveyor belt.

|

|

|

Product Name Conveyor Roller

|

Product Name : Self Cleaning Finned Tail Pulley

|

|

Diameter

|

76-219mm

|

|

Length

|

190-3500mm

|

|

Color

|

OEM

|

|

Bearing No

|

6204, 6205, 6305, 6306, 6307, 630

|

|

Standard

|

ISO/DIN

|

|

Tube Material

|

Carbon Steel

|

|

Shaft Material

|

Cold Drawing Round Steel

|

|

Shaft Diameter

|

20mm, 30mm , 35mm, 40mm

|

|

Pipe Thickness

|

3mm,35mm, 4mm&OEM

|

Specification

|

D(mm)

|

L(mm)

|

Bearing model

|

|

89

|

180,190,200,235,240,250,275,280,305,215,350,375,380,455,465,600,750,950,1150

|

204

|

|

108

|

190,200,240,250,305,315,360,375,380,455,465,525,530,600,700,750,790,800,950,1150,1400,1600

|

204 205 305 306

|

|

133

|

305,375,380,455,465,525,530,600,700,750,790,800,900,950,1000,1100,1150,1400,1600,1800,2000,2200

|

205 305 306

|

|

159

|

375,380,455,465,525,530,600,700,750,790,800,900,1000,1050,1100,1120,1150,1250,1400,1500,1600,1700,

1800,2000,2200,2500,2800,3000,3150 |

305 306 308

|

|

193.7

|

2200,2500,2800,3000,3150,3350

|

308 310

|

|

217

|

600,640,1050,1120,1600,1700,3150,3350

|

308 310

|

|

D(mm)

|

L(mm)

|

Bearing model

|

|

89

|

190,200,230,240,280,305,315,375,380,455,465,600,750,950,1150

|

204

|

|

108

|

190,200,240,250,305,315,375,380,455,465,525,600,700,750,800,950,1150,1400

|

205

|

|

133

|

305,350,375,380,455,525,530,600,700,790,800,950,1150,1400,1600

|

305

|

|

159

|

375,380,455,465,525,600,630,640,670,700,750,790,800,900,950,1050,1120,1150,1400,1600

|

306 308

|

PECPL Rollers & Conveyors

Bridging the gap between material handling and technology. Change the way of conveying by using Precisely made bulk material handling conveyor system. Customized according to your need. Idler Roller manufacturer.

Q: What materials is the Self Cleaning Finned Tail Pulley made from?

A: The Self Cleaning Finned Tail Pulley is typically made from high-quality materials such as mild steel, stainless steel, or aluminum.

Q: What is the purpose of the Self Cleaning Finned Tail Pulley?

A: The Self Cleaning Finned Tail Pulley is designed to remove material buildup from the tail pulley in conveyor systems, to ensure smooth and efficient operation of the conveyor.

Q: Can the Self Cleaning Finned Tail Pulley be customized?

A: Yes, the Self Cleaning Finned Tail Pulley can be customized to suit specific requirements, such as different sizes, materials, and bearing types.

Q: What industries are the Self Cleaning Finned Tail Pulley commonly used in?

A: The Self Cleaning Finned Tail Pulley is commonly used in heavy-duty industries such as mining, quarrying, and construction.

There are no reviews yet.