₹1,499 Original price was: ₹1,499.₹999Current price is: ₹999.

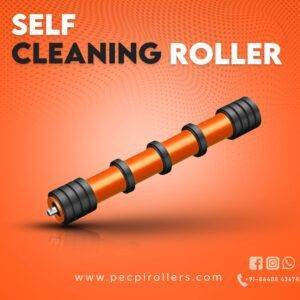

Roll Offset Impact

PECPL Conveyors & RollersIdler| Material: | Roll Offset Impact idlers are typically made from high-quality steel, with the roll shell being constructed from a variety of materials such as high-density polyethylene (HDPE), rubber, or ceramic |

|---|---|

| Application: | Roll Offset Impact idlers are typically used in applications where heavy, abrasive materials are being conveyed, such as in the mining and quarrying industries. They are also used in applications where the conveyor belt is subjected to high impact forces, such as in loading zones or transfer points |

| Structure: | Roll Offset Impact idlers typically consist of a steel frame, with a roll offset design that helps to reduce the impact force on the belt. The roll shell is typically made from a material that is designed to reduce friction and wear on the belt |

| Bearing Type: | Roll Offset Impact idlers typically use high-quality, sealed bearings that are designed to withstand heavy loads and reduce friction |

| Type: | Roll Offset Impact idlers are available in a range of sizes and configurations to suit different conveyor applications. They can be manufactured with different roll shell materials, bearing types, and frame structures |

| Transport Package: | Roll Offset Impact idlers are typically shipped in crates or on pallets to ensure safe transportation and handling |

| Samples: | Manufacturers of Roll Offset Impact idlers may offer samples to potential customers to allow them to evaluate the product before making a purchase. |

|---|

| Customization: | Roll Offset Impact idlers can be customized to meet the specific requirements of different conveyor systems. Customization options may include roll shell material, bearing type, frame structure, and size |

|---|

Description

Basic Info.

Roll Offset Impact idlers are conveyor components designed to reduce belt damage in high-impact loading applications.

They feature a unique roll offset design that helps to reduce the impact force on the belt.

They are typically made from high-quality steel, with a roll shell constructed from materials such as HDPE, rubber, or ceramic.

They are used in applications where heavy, abrasive materials are being conveyed, such as in the mining and quarrying industries.

They are available in a range of sizes and configurations to suit different conveyor applications.

Product Description

Product Description

Roll Offset Impact idlers are a type of conveyor component that helps to reduce belt damage in high-impact loading applications. They feature a unique roll offset design that helps to reduce the impact force on the belt, extending the life of the conveyor system. These idlers are typically made from high-quality steel, with a roll shell constructed from materials such as HDPE, rubber, or ceramic. They are used in applications where heavy, abrasive materials are being conveyed, such as in the mining and quarrying industries. Roll Offset Impact idlers are available in a range of sizes and configurations to suit different conveyor applications.

Roller Properties When selecting Roll Offset Impact idlers, it is important to consider the specific requirements of the conveyor system. Factors to consider may include the weight and size of the material being conveyed, the speed and angle of the conveyor, and the operating conditions of the application. Other factors to consider may include the roll shell material, bearing type, and frame structure. | |

Product Name Conveyor Roller | Product Name : Roll Offset Impact |

Diameter | 76-219mm |

Length | 190-3500mm |

Color | OEM |

Bearing No | 6204, 6205, 6305, 6306, 6307, 630 |

Standard | ISO/DIN |

Tube Material | Carbon Steel |

Shaft Material | Cold Drawing Round Steel |

Shaft Diameter | 20mm, 30mm , 35mm, 40mm |

Pipe Thickness | 3mm,35mm, 4mm&OEM |

Specification

D(mm) | L(mm) | Bearing model |

89 | 180,190,200,235,240,250,275,280,305,215,350,375,380,455,465,600,750,950,1150 | 204 |

108 | 190,200,240,250,305,315,360,375,380,455,465,525,530,600,700,750,790,800,950,1150,1400,1600 | 204 205 305 306 |

133 | 305,375,380,455,465,525,530,600,700,750,790,800,900,950,1000,1100,1150,1400,1600,1800,2000,2200 | 205 305 306 |

159 | 375,380,455,465,525,530,600,700,750,790,800,900,1000,1050,1100,1120,1150,1250,1400,1500,1600,1700, 1800,2000,2200,2500,2800,3000,3150 | 305 306 308 |

193.7 | 2200,2500,2800,3000,3150,3350 | 308 310 |

217 | 600,640,1050,1120,1600,1700,3150,3350 | 308 310 |

D(mm) | L(mm) | Bearing model |

89 | 190,200,230,240,280,305,315,375,380,455,465,600,750,950,1150 | 204 |

108 | 190,200,240,250,305,315,375,380,455,465,525,600,700,750,800,950,1150,1400 | 205 |

133 | 305,350,375,380,455,525,530,600,700,790,800,950,1150,1400,1600 | 305 |

159 | 375,380,455,465,525,600,630,640,670,700,750,790,800,900,950,1050,1120,1150,1400,1600 | 306 308 |

Roll Offset Impact idlers are typically used in applications where heavy, abrasive materials are being conveyed, such as in the mining and quarrying industries. They are also used in applications where the conveyor belt is subjected to high impact forces, such as in loading zones or transfer points.

PECPL Rollers & Conveyors

Bridging the gap between material handling and technology. Change the way of conveying by using Precisely made bulk material handling conveyor system. Customized according to your need. Idler Roller manufacturer.

Yes, we welcome sample order to test and check quality. Just mail [email protected] or contact us +91 844-004-3678

Q2. What about the lead time?

1) 2–3 days for sample

2) 20–30 days for mass production. If urgent, we have green channel.

Q3. Do you have any MOQ limit for roll offset impact order?

Low MOQ, 1pc for sample checking is available

Q4. Is it OK to print my logo on roll offset impact product?

Yes. Please inform us your logo or design before mass production

Q5. How to guarantee your quality?

We are one of the top suppliers of International famous mining company over years. Excellent quality is well accepted.

Please contact us for more details.

There are no reviews yet.