DELIVERING QUALITY SINCE 1989

PECPL Rollers & Conveyors

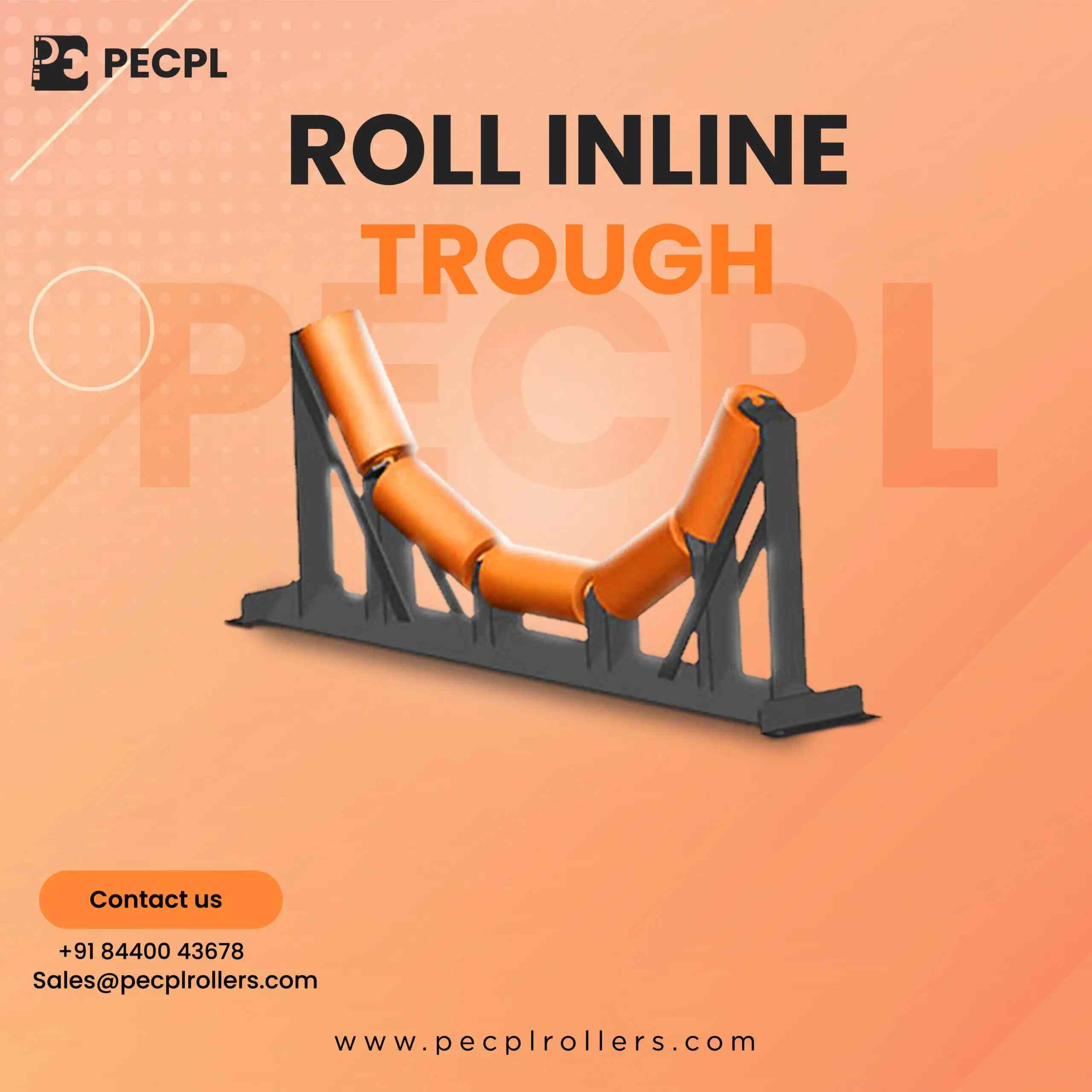

Bridging the gap between material handling and technology. Change the way of conveying by using Precisely made bulk material handling conveyor system. Customized according to your need.Idler Roller manufacturer

Perfect Engineering Component Private limited

India's Largest Roller Manufacturer

Rugged construction

Precision manufacturing

0º C to 100º C

life- maintenance free

Smooth running

Require Less Power

Efficient and Durable Conveyor Roller Solutions for Streamlined Material Handling

Special Features of Composite Rollers

Some potential features of composite conveyor rollers could include:

Lightweight: Composite materials can be much lighter than traditional steel or aluminum rollers, making them easier to install and reducing energy costs.

Durable: Composite materials are often resistant to corrosion, abrasion, and other forms of wear and tear, making them ideal for use in harsh environments or with heavy loads.

Low Noise: Composite rollers can provide a quieter conveyor operation compared to traditional metal rollers, which can be especially useful in environments where noise pollution is a concern.

High Strength-to-Weight Ratio: Composite materials can have a higher strength-to-weight ratio than traditional materials, meaning they can handle heavy loads while still remaining lightweight.

Customizable: Composite rollers can be designed and manufactured to meet specific customer requirements, such as different sizes, shapes, and surface finishes.

Low Maintenance: Composite rollers may require less maintenance than traditional metal rollers, due to their resistance to corrosion and wear, potentially reducing downtime and repair costs.

Environmentally Friendly: Composite materials can be made from recycled materials or renewable resources, making them a more sustainable choice for conveyor systems.

Features

Standards

ISO 1537:2015

ASME B20.1

DIN 22101

JIS B8805

Sealing System

Moisture protection

Improved performance

Customizable options

Circlip

Range of Diameters Offered

2 in.(51 mm)

2.5 in.(64 mm)

3 in.(76 mm)

3.5 in.(89 mm)

4 in.(102 mm)

5 in.(127 mm)

6 in. (152 mm)

Corrosion Protection and Lubrication

FOUNDATION IN 1989 by Mr. Ishwar Saini

Perfect Engineering Components (P) Ltd.

PECPL Rollers & Conveyors, a leading manufacturer of Conveyor Products. We specialize in producing high-quality components for bulk material handling systems used in various industries.

99%

On-Time Deliveries

100-1000 -> 6 Days

1000+ -> Email us at sales@pecplrollers.com

91%

Repeated Orders

Due to our consistent quality and reliable service, we have been receiving repeat orders from our customers.

![roller 669 [1]](https://pecplrollers.com/wp-content/uploads/2023/10/roller-669-1-scaled.jpg.jpeg)

![roller 55 [1]](https://pecplrollers.com/wp-content/uploads/2023/10/roller-55-1-scaled-1.jpg-1.jpg)